Composite Beams Design and Testing Under Axial, Bending and Shear Loads

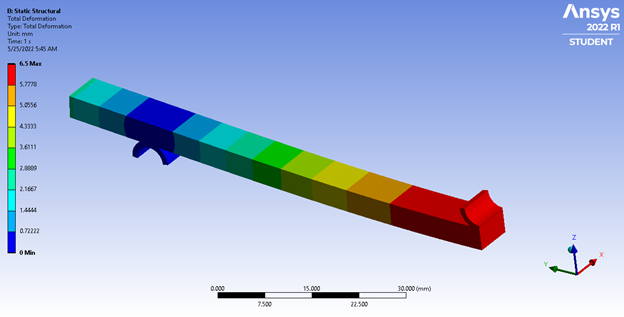

This study investigates the failure behavior of woven carbon/epoxy solid laminates with orthogonal woven plies (0/90° plain weave) subjected to three-point bending, tension, and compression in addition to investigating the applicability of unidirectional failure theories for woven plies. The analysis is conducted experimentally using material load tests and numerically using the finite element method (FEM). The carbon/epoxy laminates were examined through material characterization tests such as axial tension and compression tests, in addition to three‐point bending tests to obtain the stress limits and study the flexural behavior of the laminates. The finite element analysis is conducted using ANSYS to obtain the failure stresses using the Maximum stress, Tsai-Hill and Tsai-Wu criteria. The tested samples exhibit fiber tensile and fiber compressive failure modes where the initial failure occurs at the top ply due to compressive stresses and is shortly followed by the failure of bottom plies under tension stresses. The correlation between the numerical the experimental results is discussed, and Tsai-Hill criterion is found to correlate better with the experimental results.

Objective/Contributions:

- Composite beam analysis and testing

- Bending testing of composite beams

- Axial and shear testing of composite beams