A 3D Multiple-Slip Crystal-Plasticity Model for Precipitate Hardening in Additively Manufactured High Strength Steels

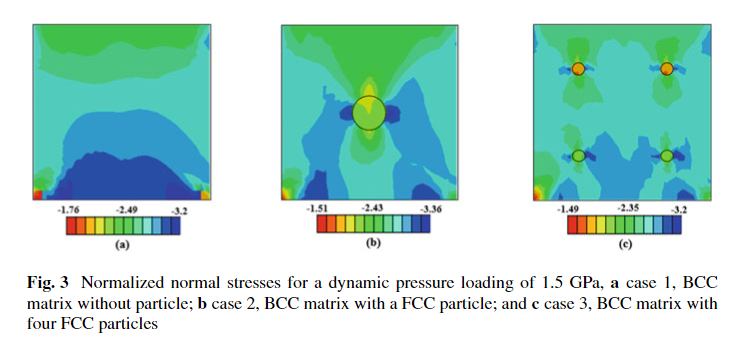

Additive Manufacturing (AM) revolutionized the manufacturing of complex geometry products, especially in medical and aerospace fields. High-strength precipitate hardened (PH) stainless steels provide unique properties in term of strength and corrosion resistance for critical applications in both fields. In the current study, a 3D multiple-slip crystal-plasticity dislocation densities-based model is used to study the effect of copper precipitate hardening in high-strength stainless steels. The proposed approach accurately predicts the complex structure of martensite and properly represents the precipitates, based on its characteristics, such as texture, morphology, secondary phases, and initial dislocation densities. The results show the effect of materials’ characteristics on mechanical properties and failure of AM-PH high-strength steels. The current work lays the groundwork for more extensive work of AM modeling. © 2022, The Minerals, Metals & Materials Society.